Poptávka podíly čelistního drtičestále roste, protože stále více lidí se spoléhá na těžbu, recyklaci a exportní průmysl.čelistní drtičtrh roste napřes 10 %každý rok, což ukazuje silnou potřebudíly drtičeFirmy se nyní zaměřují na lepšíčelistní deska drtiče čelistínávrhy a ekologická řešení, aby si udrželi náskok.

Klíčové poznatky

- Ten/Ta/Todíly čelistního drtičeTrh rychle roste díky rostoucím aktivitám ve stavebnictví, těžbě a recyklaci po celém světě.

- Nové technologieDíky automatizaci, inteligentním senzorům a lepším materiálům jsou drtiče efektivnější, odolnější a ekologičtější.

- Asijsko-pacifický region vede růst trhu, zatímco Severní Amerika a Evropa zůstávají silné; recyklace a udržitelnost jsou hnací silou budoucí poptávky.

Přehled trhu s díly pro čelistní drtiče

Projekce růstu pro rok 2025

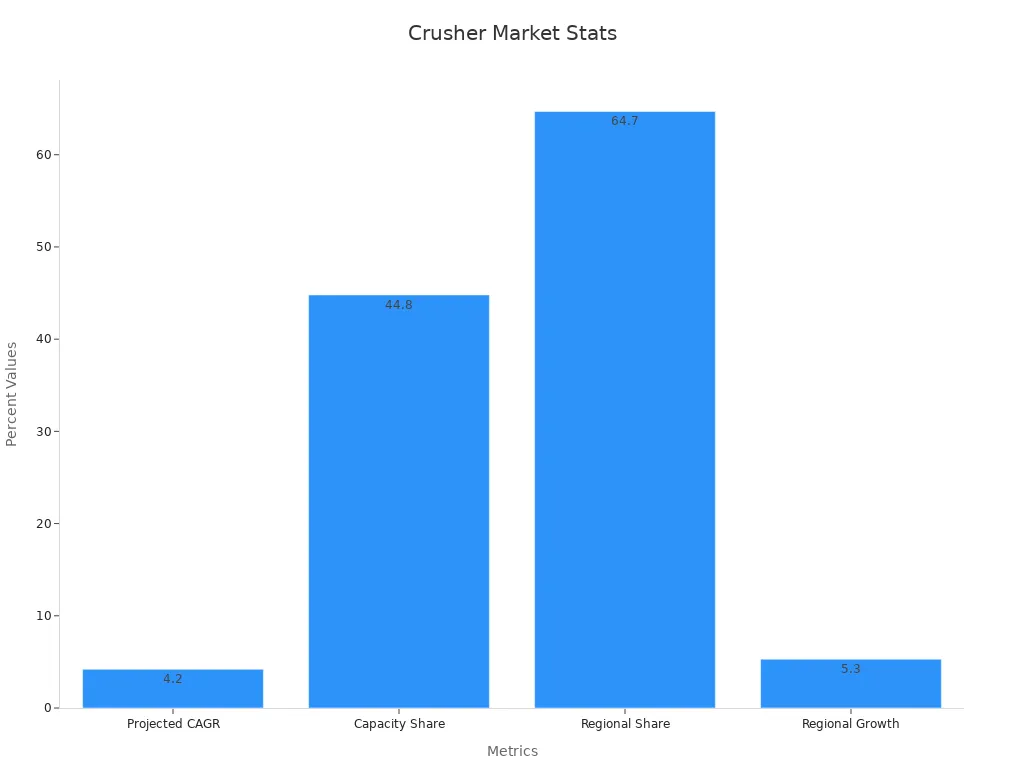

Trh s čelistními drtiči každým rokem roste. V roce 2024velikost trhu dosáhla 4,82 miliardy dolarůOdborníci očekávají stabilní růst do roku 2025, s...předpokládaná složená roční míra růstu ve výši 5,2 % od roku 2026 do roku 2033Tento růst pochází z většího počtu stavebních a těžebních projektů po celém světě. Společnosti také investují donové technologieaby drtiče fungovaly lépe a vydržely déle. Níže uvedená tabulka ukazuje některé důležité trendy, které formují trh:

| Aspekt | Podrobnosti |

|---|---|

| Tržní ocenění (2024) | 2,8 miliardy USD |

| Předpokládaná složená roční míra růstu (2025–2034) | 4,2 % |

| Klíčové faktory trhu | Rozvoj infrastruktury, rozšiřování těžebních prací,technologický pokrok (IoT, umělá inteligence, automatizace) |

| Technologické trendy | Chytré vybavení, prediktivní údržba, provozní efektivita |

| Zaměření na životní prostředí | Ekologické, energeticky úsporné, elektrické a hybridní drtiče |

| Dominantní typový segment (2024) | Jednokloubové čelistní drtiče |

| Největší segment kapacity | 100–300 TPH (44,8% podíl na trhu) |

| Tržní výzvy | Vysoké kapitálové a provozní náklady |

Klíčová odvětví pohánějící poptávku

Těžba a stavebnictví jsou v čele s využitímdíly čelistního drtiče. Očekává se, že jen těžba dosáhne do roku 2030 15,27 miliard dolarů, s vysokou mírou růstu téměř 10 % ročně. Čelistní drtiče hrají velkou roli při drcení hornin a materiálů pro tato odvětví. Urbanizace a nové infrastrukturní projekty, zejména v Asii a Tichomoří, ještě více zvyšují poptávku. Roste také recyklace, protože stále více společností hledá způsoby, jak znovu použít materiály a snížit množství odpadu.

Věděl jsi?Čelistní drtiče drží více než 38 % trhu s drtiči kamene, což ukazuje, jak důležité jsou v těžebním průmyslu a stavebnictví.

Regionální ohniska

Asijsko-pacifický region vyniká jako nejrychleji rostoucí region pro díly pro čelistní drtiče. Čína a Indie zaznamenávají obrovské investice do silnic, mostů a budov. Severní Amerika má také velký podíl, přičemž USA tvoří téměř 65 % regionálního trhu. Silný růst vykazuje i Blízký východ a Afrika díky novým těžebním a infrastrukturním projektům. Níže uvedený graf znázorňuje podíly na trhu a tempo růstu v jednotlivých regionech:

Ovladače poptávky po dílech čelistních drtičů

Infrastruktura a urbanizace

Města neustále rostou a každý rok se objevují nové silnice, mosty a budovy. Tato rychlá urbanizace zvyšuje potřebu pevných stavebních materiálů. Drcený kámen tvoří základ pro mnoho z těchto projektů a čelistní drtiče pomáhají rozbíjet horniny na použitelné kusy. S tím, jak se do měst stěhuje stále více lidí, roste poptávka po nových domech, kancelářích a veřejných prostorách. Vlády také investují do chytrých měst a lepší infrastruktury, což znamená více práce pro stavebnictví.

- Globální výdaje na infrastrukturu do roku 2025 překročí 9 bilionů dolarů.

- Rozvojové země, zejména v Asii, utratí téměř polovinu této částky.

- V roce 2023 bylo po celém světě zahájeno více než 5 000 nových infrastrukturních projektů.

- Jen indický dálniční program potřebuje každý rok 3 miliony tun drceného kameniva.

Poznámka: Mobilní a přenosné drtiče se stávají oblíbenými, protože se snadno pohybují mezi městskými a odlehlými lokalitami.

Níže uvedená tabulka ukazuje, jak různá odvětví a regiony ovlivňují poptávku po dílech pro čelistní drtiče:

| Poptávka po hnací síle / statistika | Data / Popis |

|---|---|

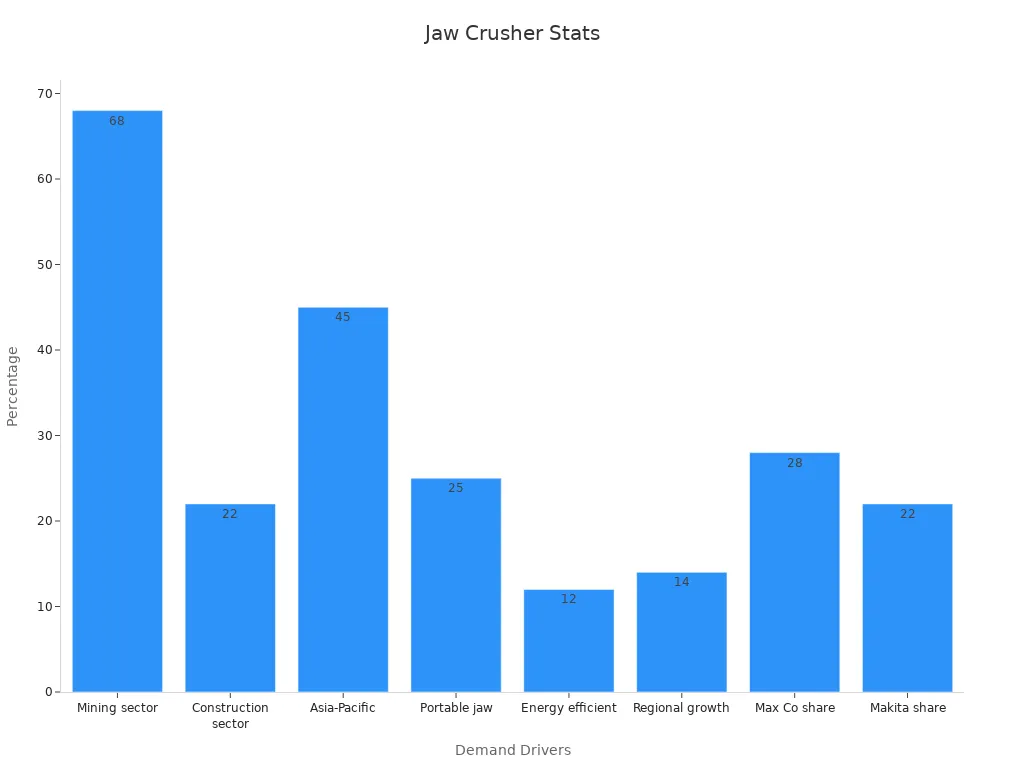

| Podíl poptávky v těžebním sektoru | Přibližně 68 % celkové poptávky po čelistních drtičích v roce 2024 |

| Podíl poptávky ve stavebnictví | Přibližně 22 % poptávky po čelistních drtičích na trhu v roce 2024 |

| Podíl na trhu v Asii a Tichomoří | Více než 45 % celosvětových dodávek čelistních drtičů v roce 2024 |

| Přenosné čelistní drtiče sdílejí | Přibližně 25 % dodávek nových zařízení na celém světě |

| Infrastrukturní projekty | Více než 5 000 nových projektů po celém světě v roce 2023 |

| Investice do výzkumu a vývoje (2023) | Do inovací technologie drtičů investováno více než 1,2 miliardy dolarů |

| Příklady regionálního růstu | Blízký východ a Afrika zaznamenaly 14% nárůst instalací nových drtičů |

| Energeticky úsporné drtiče | Elektrické jednotky se v roce 2024 podílely na prodeji nových zařízení 12 %. |

| Podíl lídrů na trhu | Max Co drží 28% podíl na trhu; Makita drží v roce 2024 22% |

Rozšíření recyklačního sektoru

Recyklace není jen trend – je to nutnost. Mnoho zemí se nyní zaměřuje na opětovné využití materiálů ze starých budov, silnic a mostů. Čelistní drtiče hrají v tomto procesu klíčovou roli. Drtí beton, asfalt a další nečistoty, aby tyto materiály mohly být znovu použity. To pomáhá snižovat množství odpadu a šetří peníze.

- Japonsko a Jižní Korea jsou v recyklaci lídry a používají drtiče ke zpracování materiálů pro nové projekty.

- Oblast Perského zálivu investuje do obnovitelných zdrojů energie a infrastruktury, což zvyšuje potřebu drtičů, které zpracovávají recyklované materiály.

- Čelistní drtiče jsou nezbytné pro primární drcení, což z nich dělá nutnost pro recyklační centra.

S tím, jak stále více společností zavádí postupy oběhového hospodářství, roste poptávka podíly čelistního drtičeroste. Tyto stroje musí tvrdě pracovat a často potřebují nové díly, aby fungovaly hladce.

Růst průmyslového exportu

Prodejzařízení čelistního drtičestále stoupá.Severní Amerika vyniká jako lídr ve vývozu pokročilých čelistních drtičůSpolečnosti jako Metso Outotec, Sandvik AB a Terex Corporation navrhují stroje s inteligentními funkcemi, jako je IoT a diagnostika pomocí umělé inteligence. Díky těmto funkcím jsou jejich drtiče populární na trzích, jako je Latinská Amerika, Asie a Tichomoří a Střední východ.

Spojené státy hrají velkou roli v globálním obchodu s drtiči,odbavuje přibližně 7 % všech dovozních zásilekIndie vede s více než polovičním podílem na trhu, zatímco Peru také vykazuje silnou poptávku. Vývozci vidí v těchto rychle rostoucích regionech velké příležitosti.

Tip: Čelistní drtiče exportní kvality často zahrnují mobilní a energeticky úsporné provedení, které oslovuje kupující zaměřené na udržitelnost a zpracování na místě.

Rostoucí poptávka ze stavebnictví, těžebního průmyslu a recyklace spolu s vládními výdaji a novými environmentálními pravidly udržuje silný exportní trh. Tento trend znamená celosvětovou větší poptávku po dílech pro čelistní drtiče.

Technologický pokrok v dílech čelistních drtičů

Automatizace a inteligentní funkce

Automatizace změnila způsob, jakým firmy používají čelistní drtiče. Dnes je mnoho strojů vybaveno inteligentními funkcemi, které pomáhají obsluze je ovládat a monitorovat na dálku. Tyto funkce usnadňují sledování výkonu a včasné odhalení problémů. Obsluha může upravovat nastavení, kontrolovat úroveň opotřebení a dokonce i spouštět nebo zastavovat stroj pomocí tabletu nebo telefonu.

- Monitorování v reálném čase umožňuje týmům každou minutu vidět, jak drtič funguje.

- Dálkové ovládání znamená, že obsluha nemusí stát vedle hlučných strojů.

- Automatizované systémy upravují rychlost podávání a nastavení drcení pro dosažení nejlepších výsledků.

Chytré funkce dělají víc než jen usnadňují život. Také zvyšují efektivitu. Automatizované systémy nastavení mohouzvýšit provozní efektivitu o 20 %Propustnost se může zvýšit o 22 %, protože se stroj přizpůsobuje změnám v materiálu. Spotřeba energie klesá přibližně o 15 %, což šetří peníze a pomáhá životnímu prostředí. Náklady na údržbu klesají až o 30 %, protože systém se dokáže sám mazat a varovat před opotřebovanými díly. Tato vylepšení vedou k menšímu počtu poruch a delší pracovní době.

Tip: Společnosti, které využívají automatizaci a chytré funkce, často zaznamenávají méně prostojů a vyšší produktivitu.

Zde je tabulka, která ukazuje některé znejnovější technologický pokroka jejich dopad:

| Technologický pokrok | Popis | Dopad na trh s díly pro čelistní drtiče |

|---|---|---|

| AI, automatizace a stroje řízené PLC | Stroje využívají umělou inteligenci a PLC pro přesné a flexibilní řízení. | Lepší účinnost, vyšší kvalita a úspory energie. |

| Hybridní a elektrické pohony | Dieselelektrické a hybridní pohony mají nižší emise a spotřebu energie. | Podporuje udržitelnost a růst trhu. |

| Pokročilé senzorové systémy a video technologie | Senzory a kamery monitorují drtiče v reálném čase. | Méně prostojů, vyšší produktivita a spolehlivost. |

| Zlepšený tok materiálu a vysoká kapacita | Větší rozevření čelistí a lepší konstrukce proudění zvyšují propustnost. | Vyšší produktivita, větší poptávka po pokročilých dílech. |

| Materiály odolné proti opotřebení a inteligentní vložky | Nové materiály a vložky IoT sledují opotřebení a vydrží déle. | Delší životnost dílů, snadnější údržba, rozšíření trhu. |

Inovace materiálů a designu

Změny materiálů a konstrukce učinily čelistní drtiče silnějšími a spolehlivějšími. Výrobci nyní používají speciální slitiny, které vydrží déle a odolávají opotřebení. Například některé společnosti používají manganovou ocel smíchanou s karbidem chromu. Tato směs činí díly téměř dvakrát tvrdšími než běžná ocel. Tyto nové materiály mohou…díly vydrží o 30 % až 60 % déle.

Důležitý je i design. Jednodušší konstrukce s menším počtem pohyblivých částí znamenají méně možných potíží. Lehčí díly usnadňují přemisťování a instalaci drtiče. Nastavitelné nastavení výtoku umožňuje obsluze zvolit velikost drceného materiálu. Agresivnější drticí zdvihy pomáhají podávat více materiálu strojem, což zvyšuje efektivitu.

Zde je několikklíčové metriky designu a materiálů:

| Metrika / Funkce | Popis / Výhoda |

|---|---|

| Redukční poměr | Kontroluje velikost a kvalitu produktů, pomáhá šetřit peníze. |

| Jednodušší design | Méně dílů, snadnější oprava a nižší náklady. |

| Lehčí | Snadnější přemisťování a instalace, šetří čas a peníze. |

| Nastavitelný výtok | Umožňuje uživatelům vybrat velikost drceného materiálu. |

| Vyšší propustnost | Přesouvá více materiálu, zvyšuje efektivitu. |

| Náklady na údržbu | Nižší kvůli lepším materiálům a jednoduššímu designu. |

Digitální nástrojetaké pomáhají. Operátoři mohou pomocí živých dat a analýz upravovat nastavení a udržovat drtič v plynulém chodu. To znamená menší opotřebení, vyšší výkon a nižší spotřebu energie.

Poznámka:Aditivní výroba, neboli 3D tisk, začíná pomáhat s výrobou zakázkových vložek pro drtiče. To umožňuje firmám vytvářet díly, které přesně odpovídají jejich potřebám.

Umělá inteligence a prediktivní údržba

Umělá inteligence (AI) významně mění způsob, jakým se firmy starají o své čelistní drtiče.Systémy umělé inteligence zkoumají data ze senzorů, aby předpověděly, kdy by mohla součástka selhatTo pomáhá týmům řešit problémy dříve, než způsobí poruchu. Prediktivní údržba může zkrátit prostoje až o 30 % a snížit neočekávané odstávky o 40 %.

Umělá inteligence dokáže víc než jen odhalovat problémy. Učí se z minulých dat, aby lépe předpovídala budoucí problémy. Některý software dokonce umožňuje týmům komunikovat se systémem pomocí přirozeného jazyka, což usnadňuje plánování oprav. Například Bayer CropScience využívá nástroje umělé inteligence ke zlepšení plánování údržby a snížení neplánovaných prostojů.

- Systémy řízené umělou inteligencí pomáhají týmům jednat rychle a udržovat stroje v chodu.

- Automatizovaný sběr dat zajišťuje, že systém má vždy k dispozici nejnovější informace.

- Prediktivní údržba prodlužuje životnostdíly čelistního drtičea snižuje náklady.

Moderní čelistní drtiče se často dodávají s modulární konstrukcí a pokročilou automatizací.Díky těmto funkcím jsou stroje spolehlivější a snadněji se udržují. Společnosti, které využívají umělou inteligenci a prediktivní údržbu, zaznamenávají méně poruch, delší životnost dílů a lepší výkon.

Věděl jsi?Chytré vložkyDíky integraci IoT mohou odesílat upozornění, když je potřeba je vyměnit, takže operátoři nikdy nezmeškají čas na údržbu.

Trendy udržitelnosti v dílech čelistních drtičů

Ekologické materiály a designy

Výrobci se nyní zaměřují na výrobu drtičů, které pomáhají planetě. Používají nové materiály achytré návrhysnižovat množství odpadu a šetřit energii. Mnoho společností začalo používat elektrické nebo hybridní zdroje energie. Tento posun pomáhá snižovat znečištění a náklady na palivo. Zde jsou některé trendy, které formují toto odvětví:

- Více než 60 % nových drtičů v roce 2023použitý elektrický nebo hybridní pohon.

- Společnosti jako Sandvik, Metso a Terex investují do výzkumu lepších a ekologičtějších strojů.

- Energeticky úsporný drtič od společnosti Sandvik snižuje náklady přibližně o 15 %.

- Hybridní drtič Metso spotřebovává o 20 % méně energie než starší modely.

- Chytré drtiče s funkcemi IoT vzrostly za pět let o 35 %.

- Přísná pravidla v Evropě nutí firmy k používání ekologických materiálů a designů.

- Elektrické drtiče mohou snížit náklady na palivo až o 25 %.

Tyto změny ukazují, že se odvětví stará jak o životní prostředí, tak o úsporu peněz.

Energetická účinnost a snižování emisí

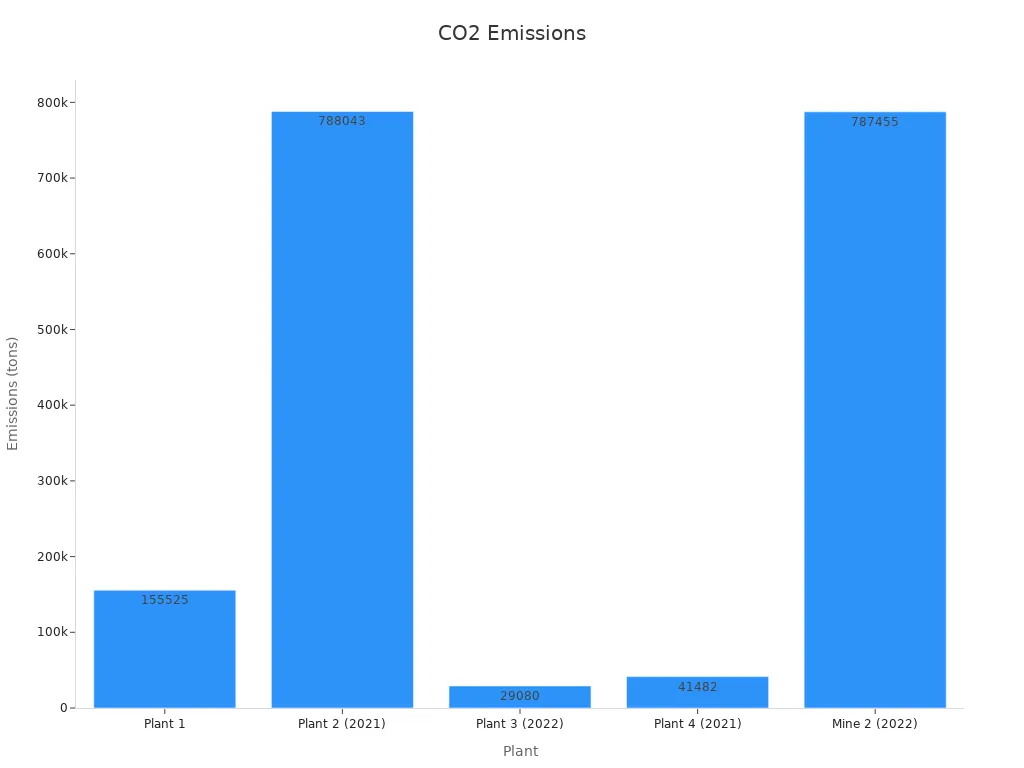

Spotřeba energie a emise jsou důležitější než kdy dříve. Rostliny, které spotřebovávají méně energie a produkují méně emisí, pomáhají chránit životní prostředí. Níže uvedená tabulka ukazuje, jak různé závody hospodaří s energií a emisemi:

| Závod / Důl | Index energetické náročnosti (GJ/tuna) | Celkové emise CO2 (tuny) | Klíčová pozorování |

|---|---|---|---|

| Rostlina 1 | EII-Au ↓ 12 % | 155 525 | Dobrá regulace energie, nižší emise |

| Rostlina 2 | EII-Au ↓ 25 %, EII-Cu ↓ 37 % | 788 043 | Vysoká spotřeba energie, rostoucí emise |

| Rostlina 3 | EII-Au ↑ 88 % | 29 080 | Stabilní emise, prostor pro zlepšení |

| Rostlina 4 | EII-Au ↑ 2842 % | 41 482 | Vysoká energie a emise |

Závody, které využívají elektrickou energii a inteligentní systémy, mohou snížit emise a ušetřit energii. Mletí spotřebovává nejvíce energie, takže nové technologie pomáhají snižovat odpad. Společnosti také využívají uhlíkové kredity k investicím do čistších strojů.

Cirkulární ekonomika a řízení životního cyklu

Průmysl nyní přemýšlí o celé životnosti každého dílu. Firmy recyklují staré díly a používají materiály, které vydrží déle. Navrhují drtiče, aby pracovníci mohli díly snadno vyměnit, což znamená méně odpadu. Chytré senzory pomáhají sledovat, kdy je třeba díly vyměnit, takže se nic nevyhodí příliš brzy. Tento přístup podporuje cirkulární ekonomiku, kde se zdroje používají znovu a znovu.

Poznámka: Když se firmy zaměřují na řízení životního cyklu, šetří peníze a zároveň pomáhají planetě.

Investiční příležitosti a tržní výzvy

Regiony a sektory s vysokým růstem

Investoři vidí velké příležitosti v regionech, kde stavebnictví a těžba zažívají boom. Severní Amerika vyniká díky své silnéinfrastrukturní projekty a pokročilé technologieSpolečnosti tam využívají umělou inteligenci a elektrické pohonné systémy, aby drtiče byly chytřejší a čistší. Asijsko-pacifický region, zejména Čína a Indie, rychle roste díky novým silnicím, budovám a továrnám. Tyto země investují do průzkumu nerostných surovin a moderního vybavení. Evropa také investuje do dálnic a železnic, zatímco Latinská Amerika a Afrika jeví slibné růsty s expanzí jejich těžebního a stavebního sektoru.

| Kraj | Faktory růstu a odvětví |

|---|---|

| Severní Amerika | Přední výrobci, růst stavebnictví, výzkum a vývoj energeticky úsporných drtičů |

| Asie a Tichomoří | Rychlá industrializace, investice do infrastruktury, těžba nerostných surovin |

| Evropa | Vysoké investice do infrastruktury, zavedený těžební průmysl |

| Latinská Amerika, Střední východ a Afrika | Rostoucí infrastruktura a těžba, ale pomalejší kvůli pracovním a politickým problémům |

Tip: Poptávku po materiálu zvyšují i odvětví jako recyklace, výroba kameniva a hutnictví.pokročilé díly drtiče.

Tržní bariéry a omezení

Trh čelí několika výzvám. Vysoké počáteční náklady ztěžují malým firmám nákup nových strojů. Problémy s dodavatelským řetězcem, jako jsou zpoždění v dodávkách dílů, mohou zpomalit projekty. Ceny oceli se často mění, což ztěžuje plánování rozpočtů. Některé firmy se potýkají s hledáním kvalifikovaných pracovníků pro provoz a opravy drtičů. Nová pravidla týkající se hluku a emisí znamenají vyšší náklady pro všechny. Obchodní bariéry, jako jsou cla v USA, zvyšují ceny a nutí firmy hledat nové dodavatele.

- Vysoké investiční náklady omezují malé provozovatele.

- Zpoždění a nedostatek klíčových dílů zvyšují náklady.

- Kolísající ceny oceli ovlivňují plánování.

- Nedostatek kvalifikované pracovní síly snižuje využívání strojů.

- Přísnější environmentální pravidla zvyšují náklady.

- Změny cel a obchodu narušují dodavatelské řetězce.

Strategické přístupy pro vstup na trh

Firmy používají chytré strategie k úspěchu na tomto trhu. Mnohoinvestovat do výzkumu s cílem vytvořit drtiče s hybridním pohonem a digitálními funkcemiPartnerství s těžebními a stavebními firmami jim pomáhá oslovit více zákazníků. Expanze do rychle rostoucích regionů, jako je Asie a Tichomoří a Latinská Amerika, rozkládá riziko a zvyšuje prodej. Služby zaměřené na zákazníka, jako je školení a poprodejní podpora, budují loajalitu. Některé společnosti využívají přímý prodej, zatímco jiné spolupracují s distributory nebo prodávají online, aby oslovily více kupujících. Zaměření na udržitelnost a nové technologie dává společnostem výhodu oproti konkurenci.

Poznámka: Firmy, které plánují rizika dodavatelského řetězce a investují do digitálních nástrojů, si často udržují náskok na měnícím se trhu.

Regionální poznatky o dílech čelistních drtičů

Přední trhy: Severní Amerika, Evropa, Asie a Tichomoří

Severní Amerika, Evropa a Asie a Tichomoří vedouv odvětví čelistních drtičů. Každý region má své silné stránky a důvody pro růst. Severní Amerika vyniká jako lídr na trhu. Společnosti v USA a Kanadě se zaměřují na nové technologie a lepší výkon drtičů. Evropa drží druhý největší podíl na trhu. Německo vede v prodeji, zatímco Velká Británie roste nejrychleji. Poptávku v tomto regionu pohání nemovitosti a velké stavební projekty. Asie a Tichomoří rostou nejrychleji ze všech. Čína má největší podíl a Indie ji rychle dohání. Mnoho továren a dolů v těchto zemích potřebuje silné a spolehlivé drtiče.

Zde je rychlý přehled nejlepších regionů:

| Kraj | Pozice na trhu | Klíčové faktory růstu | Přední země | Významné trendy |

|---|---|---|---|---|

| Severní Amerika | Lídr na trhu | Technologické inovace, pokročilé funkce drtiče | USA, Kanada | Zaměření na výkon a chytré funkce |

| Evropa | Druhý největší podíl na trhu | Nemovitosti, stavebnictví, infrastruktura | Německo, Spojené království | Poháněno stavebními projekty a rekonstrukcemi |

| Asie a Tichomoří | Nejrychlejší složená roční míra růstu (2023–2032) | Těžba, stavebnictví, recyklace | Čína, Indie | Cenově výhodné, odolné a produktivní drtiče |

Velké společnosti jako Sandvik, Terex a Metso investují do výzkumu a spolupracují s místními partnery. Uvádějí na trh nové produkty a zřizují továrny blízko zákazníků. To jim pomáhá snižovat náklady a oslovovat více kupujících.

Rozvíjející se regiony a nevyužitý potenciál

Některé regiony na tomto trhu teprve začínají růst. Latinská Amerika, Blízký východ a Afrika vykazují stabilní pokrok. V těchto oblastech se každý rok objevuje více těžebních a stavebních projektů. Mnoho společností vidí tato místa jako další velkou příležitost.

- Větší poptávka po speciálních čelistních drtičích pochází ze stavebnictví, těžebního průmyslu a recyklace.

- Města v Číně a Indii neustále rostou, což znamená více silnic a budov.

- Latinská Amerika a Afrika investují do těžby a nové infrastruktury.

- Recyklace a ekologické stavebnictví vyžadují drtiče, které zvládají staré materiály.

- Firmy se podívají na zprávy a odborné recenze, aby našly nejlepší oblasti pro růst.

- Globální i lokální značky se snaží v těchto regionech expandovat, aby získaly nové kupce.

Poznámka: Vzhledem k tomu, že se stále více zemí zaměřuje na recyklaci a udržitelnost, bude potřeba drtičů v těchto regionech pravděpodobně nadále růst.

Trh neustále roste, protože těžba, stavebnictví a nové technologie zvyšují poptávku. Společnosti vidí silné příležitosti, ale čelí výzvám, jako je nedostatek surovin a přísná pravidla.

| Aspekt | Podrobnosti |

|---|---|

| Tržní ocenění 2024 | 1,5 miliardy USD |

| Předpokládané ocenění 2033 | 2,8 miliardy USD |

| Roční roční míra růstu (2026–2033) | 7,5 % |

| Výhled trhu | Pozitivní a expandující |

Často kladené otázky

K čemu se používají díly čelistních drtičů?

Díly čelistního drtičepomáhají rozbíjet kameny a další tvrdé materiály. Lidé je používají v těžbě, stavebnictví a recyklaci k výrobě menších kusů pro stavbu nebo opětovné použití.

Proč roste trh s díly pro čelistní drtiče?

Stále více měst potřebuje nové budovy a silnice. Firmy chtějí recyklovat staré materiály. Tyto potřeby zvyšují poptávku po pevných a spolehlivých dílech pro čelistní drtiče.

Jak nové technologie pomáhají s díly čelistních drtičů?

Chytré funkce a lepší materiály dělajídíly čelistního drtiče vydrží déleTaké pomáhají strojům spotřebovávat méně energie a potřebovat méně oprav. To šetří peníze a čas.

Post time: Jul-07-2025